Plaster finishes: Plaster finish plays an important role in various types of social and civil construction projects. It is used to make the walls and ceilings of construction works smooth and rendered, and its main purpose is to provide beauty and durability to the walls. It includes different types of plaster finishes, such as smooth finish, textured finish, textured patty, and pop (plaster of paris) finish.

These use a variety of plaster mixes and techniques to create attractive and expert looks as per construction projects, and fit into architectural designs. Plaster finish makes the walls stronger. And also protects from water leakage. So in this article we will know how many types of plaster types are there. Along with this we will also understand how many types of plasters, plastering types, plaster types are there. So stay tuned to this article.

How many types of plaster are there?

There are three types of plaster mainly contain either gypsum, lime, or cement. And they all work in the same way. The plaster is manufactured as a dry powder and is mixed with water to form a stiff but workable paste immediately before it is applied to the surface.

1. Lime Plaster

Lime plaster is an ancient and traditional building material used in laying the foundations of buildings and structures. It is made with an inner mixture of lime, water, and sand and then used to cover walls and ceilings. This plaster is permanent and environment friendly, which makes the walls attractive as well as safe. Lime plaster is used in this way.

2. Cement Plaster

Cement plaster is a major construction material. Which is used in various types of manufacturing processes. It is used in the construction of walls, ceilings, and other structures. The mixture of cement plaster is prepared from cement, clay, water and fine sand. It is used in construction processes such as roads, buildings, homes and commercial structures. Cement plaster has many benefits. Which are given below.

Cement plaster has many benefits:

- Durability: It lines walls and ceilings and protects them from opacity.

- Safety: It also provides protection from fire and wastes.

- Durability: Cement plaster makes the walls durable for a long time, thereby increasing the longevity of the construction.

- Against external noise: It helps in reducing external noise.

After applying letters or pasting on cement plaster walls, it is easy to paint or apply wallpaper. Due to which the walls look attractive and clean.

3. Gypsum Plaster

Gypsum plaster is a construction material mixed with gypsum, water and sand. And it is used in building construction to create smooth surface of walls and ceilings.

The important benefits of gypsum plaster are:

- Safety: Gypsum plaster provides protection against fire, thereby increasing the safety of construction.

- Easy Process: It is easy to use and helps in maintaining mass of construction.

- Environment Friendly: This plaster blends in with the environment to provide a pleasant smooth surface without any viral adverse effects.

- Sound Occasions: Gypsum plaster helps in better sound absorption, so it is good for sound occasions.

Special uses of gypsum plaster include adding beauty and durability to walls and ceilings of homes, schools, hospitals, and commercial structures. It is also used in wardrobes, puja rooms, bathrooms and other interior construction as it is very suitable for providing smooth surface.

The Most Important types of plaster wall finishes

Different types of plaster finishes are available for use in different areas as follows. Which makes houses beautiful and strong. So let us know.

- Smooth cast finish

- Rough cast finish

- Sand faced finish

- Pebble dash finish

- Scrapped finish

- Depeter finish

- Textured finish

1. Smooth cast finish – Plaster Finishes

Smooth cast finish – is a manufacturing process. Which is used in plastering of walls, ceilings, or other structures. So that a smooth and yielding surface can be obtained. In this process, the plaster mixture is applied slowly and carefully so that there are no lines or untimely stops on the surface, and a beautiful and smooth finish is obtained. This type of finish looks attractive and it provides waterproofing and protection to the internal structures.

2. Rough cast finish – Plaster Finishes

Rough cast finish is a manufacturing process used in plastering of walls and ceilings to obtain a non-smooth and permanent surface. In this process, the plaster mixture is simply applied, and then rough or spit type scrapers or trowels are used to make the surface rough and uneven. This results in a rough cast finish giving a fine and textured plastering look that is attractive and strong.

3. Sand faced finish – Plaster Finishes

Sand faced finish is a manufacturing process used in plastering walls and ceilings to obtain an attractive and solid surface. In this process, the plaster mixture is simply applied, and then a special type of sand coat is used to create a rough and grainy texture on the surface. This type of finish is attractive and is especially used in interior structures where deep texture and a smooth surface are required.

4. Pebble dash finish

Pebble dash finish requires a mortar layer of 12 mm thickness with cement and sand in the ratio of 1:3. After plastering, pebbles of 10 mm to 20 mm size are poured on the plastered surface. Then, using a wooden float, gently press them onto the plastered surface so that the pebbles stick. After hardening they provide an aesthetic appearance to the structure.

5. Scrapped Plaster Finish

Scrapped Plaster Finish – To get scraped finish, apply the final coat at 6 to 12 mm thickness and let it dry for a while. After drying for some time, scrape the plastered layer to a depth of 3 mm using a steel blade or plate. Due to which the possibility of cracking is very less.

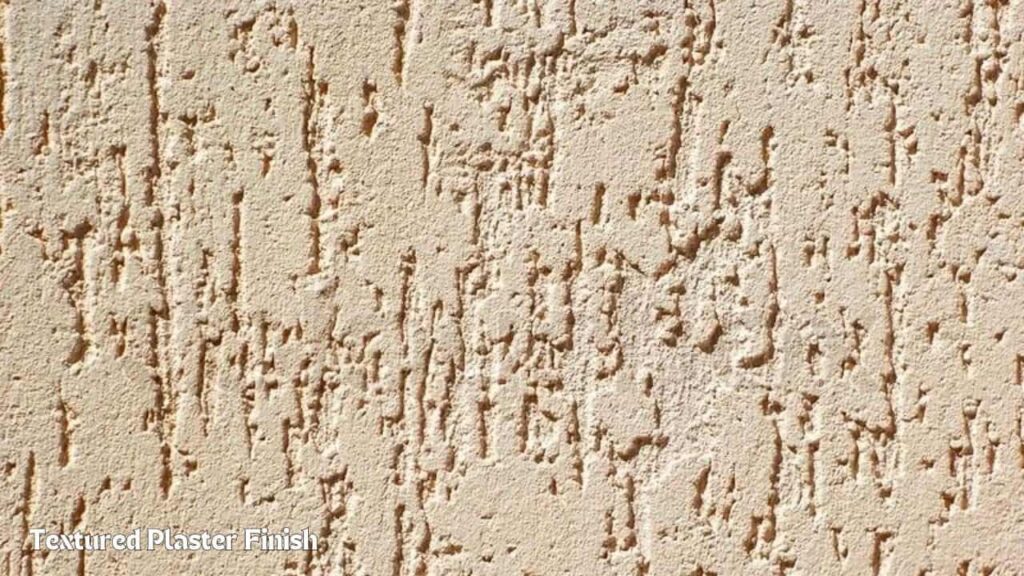

6. Textured Plaster Finish

Textured Plaster Finish – Textured finish is obtained by plastering. In which different types of textures or shapes can be created on the final coat by using suitable equipment.

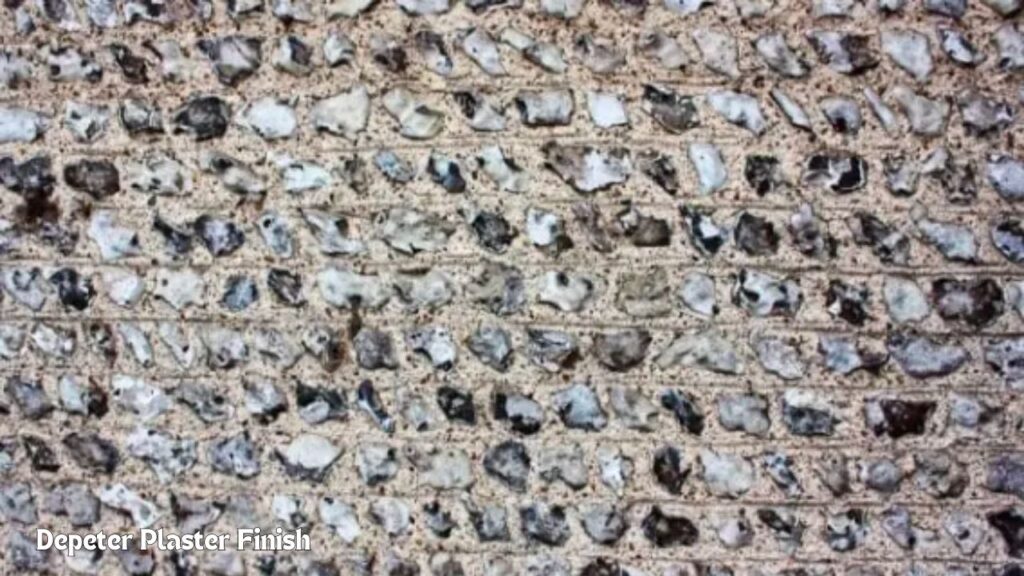

7. Depeter Plaster Finish

Depeter Plaster Finish – This is also similar to pebble dash finish. But in this case, instead of pebbles, gravel or flint pieces are used.